Surface Mount Technology (SMT): Revolutionizing Modern Electronics

Surface Mount Technology (SMT) is a method for producing electronic circuits in which the components are mounted directly onto the surface of printed circuit boards (PCBs). This technology has revolutionized the electronics industry by enabling the miniaturization of devices, improving manufacturing efficiency, and enhancing the overall performance and reliability of electronic products. In this article, we will explore the history, development, and impact of SMT, as well as its advantages, components, processes, and future trends.

History and Development

The evolution of Surface Mount Technology can be traced back to the mid-20th century. Before the advent of SMT, electronic components were attached to PCBs using through-hole technology (THT). In THT, component leads were inserted into holes drilled in the PCB and soldered to pads on the opposite side. While THT provided robust mechanical connections, it had significant limitations, including larger board sizes, higher production costs, and reduced automation potential.

The transition to SMT began in the 1960s and 1970s, driven by the need for more compact and lightweight electronic devices. The aerospace and defense industries were among the first to adopt SMT due to their requirements for miniaturized and reliable components. By the 1980s, SMT started gaining widespread acceptance in consumer electronics, telecommunications, and computing industries.

Advantages of SMT

SMT offers numerous advantages over traditional through-hole technology, making it the preferred choice for modern electronic manufacturing:

Miniaturization: SMT components are significantly smaller than their through-hole counterparts, allowing for more compact and lightweight designs. This has been crucial in the development of portable electronic devices such as smartphones, tablets, and wearable technology.

Increased Component Density: SMT enables higher component density on PCBs, meaning more functionality can be packed into a smaller area. This leads to more powerful and feature-rich electronic devices.

Improved Performance: SMT components typically have shorter leads, resulting in lower parasitic inductance and capacitance. This enhances the electrical performance of circuits, especially at high frequencies.

Cost Efficiency: SMT simplifies the manufacturing process by eliminating the need for drilling holes and manual insertion of components. This reduces labor costs and increases production speed, making it a cost-effective solution for large-scale manufacturing.

Automated Production: SMT is well-suited for automation, allowing for high-speed, high-precision assembly lines. This results in consistent quality and reduces the likelihood of human error.

Reliability: SMT components are often more reliable due to their smaller size, lower mass, and better thermal characteristics. They are less prone to mechanical stress and vibration.

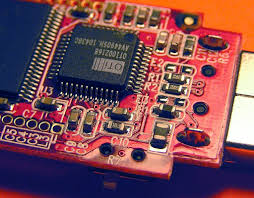

SMT Components

SMT components are designed to be mounted directly onto the surface of PCBs. These components come in various packages, each suited to specific applications. The most common SMT component packages include:

Chip Resistors and Capacitors: These are among the smallest SMT components, typically available in standard sizes such as 0402, 0603, and 0805. They are widely used in various electronic circuits for tasks such as voltage regulation, signal filtering, and impedance matching.

Integrated Circuits (ICs): ICs in SMT come in a variety of packages, including Small Outline Integrated Circuits (SOICs), Thin Small Outline Packages (TSOPs), and Quad Flat Packages (QFPs). These packages accommodate complex circuits with multiple functions, such as microprocessors, memory modules, and power management units.

Transistors and Diodes: SMT transistors and diodes are used in switching, amplification, and rectification applications. Common packages include Small Outline Transistor (SOT) and Surface Mount Diode (SMD) packages.

Connectors: SMT connectors are used to establish electrical connections between different parts of a circuit or between different devices. They are available in various configurations, including board-to-board, cable-to-board, and input/output connectors.

Passive Components: In addition to resistors and capacitors, other passive components such as inductors and filters are also available in SMT packages. These components play crucial roles in signal conditioning and power management.

SMT Process

The SMT assembly process involves several key steps, each crucial for ensuring the reliability and performance of the final product. The main stages of the SMT process are:

Solder Paste Application: The process begins with the application of solder paste to the PCB. Solder paste, a mixture of solder particles and flux, is applied to the board using a stencil. The stencil has openings that correspond to the pads where components will be placed.

Component Placement: Once the solder paste is applied, the components are placed onto the PCB using automated pick-and-place machines. These machines precisely position the components on the board based on the design specifications.

Reflow Soldering: After component placement, the PCB is subjected to a reflow soldering process. The board is passed through a reflow oven, where it is gradually heated to a temperature that melts the solder paste. This forms strong solder joints between the components and the PCB pads.

Inspection and Testing: Post-soldering, the PCB undergoes inspection and testing to ensure the quality and reliability of the assembly. Automated optical inspection (AOI) systems check for solder joint defects, misaligned components, and other issues. X-ray inspection may be used for hidden solder joints, and functional testing verifies the electrical performance of the assembled board.

Cleaning and Coating: In some cases, the assembled PCBs are cleaned to remove any flux residues or contaminants. Additionally, conformal coating may be applied to protect the board from environmental factors such as moisture, dust, and chemical exposure.

Challenges in SMT

Despite its numerous advantages, SMT also presents certain challenges that need to be addressed to ensure successful implementation:

Component Handling: The small size of SMT components makes them difficult to handle and place accurately. Advanced pick-and-place machines with high precision are required to ensure proper alignment.

Solder Paste Printing: Achieving consistent and accurate solder paste deposition is critical for reliable solder joints. Variations in paste volume or misalignment of the stencil can lead to defects such as insufficient solder, bridging, or tombstoning.

Thermal Management: SMT assemblies generate heat during operation, and effective thermal management is essential to prevent overheating and ensure long-term reliability. This may involve the use of heat sinks, thermal vias, and appropriate PCB layout techniques.

Quality Control: Ensuring the quality of SMT assemblies requires rigorous inspection and testing processes. Detecting defects in high-density assemblies can be challenging, and advanced inspection technologies are necessary.

Design Considerations: Designing for SMT involves careful consideration of factors such as component placement, pad design, and thermal relief. Engineers must follow design guidelines to optimize manufacturability and reliability.

Future Trends in SMT

The future of Surface Mount Technology is shaped by ongoing advancements in materials, processes, and automation. Several trends are expected to drive the evolution of SMT in the coming years:

Miniaturization and High-Density Packaging: As consumer demand for smaller and more powerful devices continues to grow, SMT will play a crucial role in achieving higher levels of miniaturization and component density. Innovations in packaging technologies, such as chip-scale packages (CSPs) and wafer-level packages (WLPs), will enable even more compact designs.

Flexible and Wearable Electronics: The rise of flexible and wearable electronics presents new challenges and opportunities for SMT. Flexible substrates and stretchable interconnects will require new assembly techniques and materials to ensure reliability and performance in dynamic environments.

Advanced Materials: The development of advanced materials, such as lead-free solder alloys and high-performance adhesives, will enhance the performance and environmental sustainability of SMT assemblies. These materials will also support the increasing demand for RoHS (Restriction of Hazardous Substances) compliance.

Automation and Industry 4.0: The integration of SMT assembly lines with Industry 4.0 technologies, including the Internet of Things (IoT), artificial intelligence (AI), and machine learning, will drive greater automation and efficiency. Smart factories with real-time monitoring and adaptive control will optimize production processes and reduce downtime.

3D Printing and Additive Manufacturing: The convergence of SMT with 3D printing and additive manufacturing holds promise for creating complex, multi-layered electronic assemblies with integrated components. This approach can enable new design possibilities and reduce the need for traditional assembly steps.

Environmental Considerations: Sustainability will continue to be a key focus in SMT development. Efforts to reduce electronic waste, improve energy efficiency, and develop recyclable materials will drive innovation in the industry. Green manufacturing practices and eco-friendly materials will become increasingly important.

Conclusion

Surface Mount Technology has transformed the electronics industry by enabling the development of smaller, more powerful, and more reliable devices. From its origins in the aerospace and defense sectors to its widespread adoption in consumer electronics, SMT has continually evolved to meet the demands of modern technology. The advantages of SMT, including miniaturization, increased component density, improved performance, cost efficiency, and automation, have made it the preferred choice for electronic manufacturing.

While SMT presents certain challenges, advancements in materials, processes, and automation are driving the industry forward. The future of SMT is marked by trends such as miniaturization, flexible electronics, advanced materials, automation, 3D printing, and environmental sustainability. As these trends continue to shape the landscape of electronics manufacturing, SMT will remain at the forefront of innovation, enabling the creation of cutting-edge technologies that define our modern world.

In summary, Surface Mount Technology is not just a manufacturing technique; it is a cornerstone of modern electronics that has revolutionized the way we design, produce, and interact with electronic devices. As technology continues to advance, SMT will play an even more critical role in shaping the future of electronics, driving innovation, and enabling new possibilities in various industries.